A na-ejikarị valvụ ụwa nke Yuanda Valve iji kwụsị, bido ma na-ahazi usoro mmiri na-eru na pipeline.Enwere ike iji valvụ mechiri emechi iji mechie mmiri na-asọpụta site na ịkwaga valvụ ahụ megide ntụzịaka nke eruba.A na-ahụkarị valves ndị a na ọrụ ngbanwe, mana enwere ike iji ya na ngwa dị iche iche.Yuanda Valve na-arụpụta valvụ igwe anaghị agba nchara, yana ụdị ihe ndị ọzọ dị iche iche, gụnyere nkedo ígwè, ihe nkedo na ọla.Nke a na-agụnye valvụ ndị na-eguzogide corrosion, mechie nrụgide na valvụ globe cryogenic.Ọ bụrụ na ị nwere ajụjụ ọ bụla gbasara ngwaahịa valvụ ụwa anyị na njirimara ha, biko kpọtụrụ Yuanda Valve taa!

| Aha akụkụ | Akụrụngwa |

| Isi, Bonnet | ASTM A351 |

| Disc | ASTM A351 |

| Isi | ASTM A965 |

| Mgbanaka oche | ASTM A351 |

Nka na ụzụ chọrọ na valvụ igwe anaghị agba nchara ụwa:

1. Nhazi na nrụpụta: ASME B16.34

2. Ihu na ihu: ASME B16.10

3. Ọgwụgwụ Flange: ASME B16.5

4 Igwe anaghị agba nchara Globe Valve Standard Test: Dabara na API 598

Ọkọlọtọ API na-akọwapụta ihe achọrọ maka usoro ọrụ dị arọ bolted bonnet steel globe valves maka ngwa ndị metụtara ya.

N'ime ngwa ndị a, corrosion, corrosion na ọnọdụ ndị ọzọ a na-eji eme ihe ga-egosi mkpa maka akụkụ ndị nwere mgbidi na nnukwu mkpanaka mkpanaka.

Ihe njiri mara API Globe Valve:

1. mkpuchi mkpuchi;

2. Nrụgide mkpuchi mkpuchi valvụ;

3. Ihe nkedo na ndụdụ dị n'èzí;

4. Na-atụgharị na-arị elu elu na-adịghị agbanwe agbanwe;

5. Ụkwụ aka na-arịgo na igwe anaghị arị elu;

6. Ụdị kwụ ọtọ, ụdị Y, ụdị akụkụ aka nri;

7.stop-leck (ụdị globe valves nke na-adịghị alaghachi azụ nke diski nwere ike idobe ya na oche site na ọrụ nke azuokokoosisi ma nweere onwe ya ibili dị ka valvụ nlele n'ihi na-esi n'okpuru diski ahụ na-asọpụta mgbe ọkpụkpụ ahụ dị na zuru ezu ma ọ bụ akụkụ ụfọdụ. oghere oghere);

8.plug, warara, conical, bọọlụ, ma ọ bụ diski eduzi;

9.metallic oche n'elu;

10.flanged ma ọ bụ butt-welding agwụ.

11.Ọ na-ekpuchi valves nke ọnụ ọgụgụ pipụ nha NPS:

2, 2½, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24;

12. kwekọrọ na nha ọkpọkọ aha aha DN:

50, 65, 80, 100, 150, 200, 250, 300, 350, 400, 450, 500, 600;

13.na-etinye maka ọkwa klaasị nrụgide:

150, 300, 600, 900, 1500, 2500.

Njirimara na uru igwe anaghị agba nchara Globe Valves:

1. Pụrụ iche na-abụghị n'usoro azuokokoosisi imewe na-adị mfe mgbanwe maka actuation-- na nkenke Acme eri na ọkụ imecha.Igwe anaghị agba nchara valvụ dabara adaba maka nrụnye kehoraizin.

2. Igwe anaghị agba nchara Universal trim: 13Cr stem, 13Cr disc faced, na CoCr alloy chere oche ihu - API Trim 8 kwesịrị ekwesị maka ọrụ ruo 850 F (454 C).Oche ihu CoCr alloy nwere ihu siri ike, ala ma gbadaa na enyo.A na-arụ oche conical ka ọ rụchaa nke ọma.Disiki a na-eduzi nke ahụ na-ejikọta nke ọma n'elu diski ahụ nwere ihu siri ike (nke nwere 13Cr, CoCr alloy, SS 316, ma ọ bụ Monel) n'elu oche ahụ, nke a na-agbanye n'ala ma tinye ya na enyo.Ntuziaka diski nwere ihu siri ike iji gbasaa ndụ ndụ nke ntuziaka diski.

3. Igwe anaghị agba nchara ahụ na ihe nkedo bonnet na-arụ ọrụ nkenke.Otu bonnet maka nhazi ka mma, akụkụ ole na ole.

4. Ngwongwo ihe eji eme ihe na-eme ka ọ dị mma.

5. Ahụ na bonnet nkwonkwo n'ụzọ ziri ezi machined ka mma elu imecha.gasket gbachiri nke ọma.

6. Gland nwere ihe owuwu abụọ maka nhazi dị mfe.

7. Akụ na-agbanwe agbanwe na Austenitic ductile iron Gr.D-2C, enwere ike imeghari n'ime ahịrị.

8. Torque ogwe aka ebelata iyi na mbukota yiri mgbaaka na-enyere mma akara na-ebelata torque.

9. Impactor handwheels: Globe na nkwụsị valvụ nlele na-achọ ka mgbanaka mmechi dị elu karịa ọnụ ụzọ ámá nke nwere otu oche oche na klas nrụgide.Usoro kachasị dị ọnụ ahịa maka nkwụsị nke ọma bụ wheel handwheel mmetụta.Ụkwụ abụọ nke a na-atụ n'okpuru wheel na-eti ihe n'otu oge ma na-enye 3-10 ugboro ike mmechi nke ụkwụ ụkwụ ọkọlọtọ.A na-ebunye wiilịke aka mmetụta na nhọrọ onye nrụpụta ma ọ bụrụ na ndị ahịa akọwapụtara ya.

10. Flanges: ASME Klas: 150-- 300: 116" ihu elu.

11. Klas ASME: 600-- 1500: 1/4" ihu ewelitere.

12. Ngwunye: 125-- 250 AARH maka valves niile.

Ndị a bụ ụfọdụ ngwa ngwa igwe anaghị agba nchara Globe Valves:

1. Usoro mmiri jụrụ oyi nke kwesịrị ịhazigharị ọnụego.

2. Sistemụ mmanụ ọkụ, ụkpụrụ na-asọpụta, na njigide dị oke mkpa.

3. Mgbe tightness na nchekwa bụ isi ihe dị mkpa, oghere dị elu na nkwụsịtụ ala.

4. Mmiri mmiri, nri kemịkalụ, condenser iyuzucha na ikpochapu usoro.

5. Ọdụ ụgbọ mmiri na-agbapụta mmiri na ọkpọkọ ọkpọkọ, isi ọdụ ụgbọ mmiri na-agbapụta mmiri na ọkpọkọ mmiri, na ọkpọkọ ọkpọkọ ọkụ.

6. Turbine akara na igbapu ọkpọkọ.

7. Turbine lubricating mmanụ usoro, wdg.

-

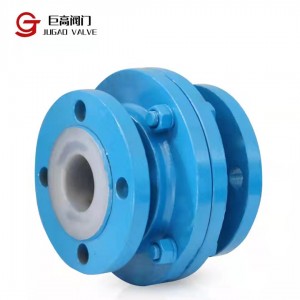

Fluorine-lined igwe anaghị agba nchara / nkedo ígwè natio ...

-

Fluorine-lined igwe anaghị agba nchara / nkedo ígwè natio ...

-

Fluorine-lined igwe anaghị agba nchara / nkedo ígwè natio ...

-

Igwe anaghị agba nchara fluorine kpuchie bọọlụ valvụ

-

Carbon ígwè fluorine lined diaphragm valve

-

Fluorine valvụ urukurubụba